Infrared Thermography is the process of using a thermal imager to detect infrared radiation (heat) that is emitted by an object. The technology allows operators to validate normal operations and, more importantly, locate thermal anomalies (abnormal patterns of heat invisible to the eye) which indicate possible faults, defects or inefficiencies within a system or machine asset.

In the infrared realm, even very cold objects emit infrared. Objects with higher temperatures emit higher levels of infrared radiation. Our experts use infrared thermography cameras to detect and measure heat levels in a range of equipment. Such testing is ideal for electrical wiring, furnaces, furnace tubes, bearings, batteries, motors, motor control centers and breakers, and more. IIPM has a proven track record in electrical surveys, insulation testing, and refractory testing for major clients such as IOCL, NRL , BCPL , NTPC , DEEPAK FERTILISER , ZUARI CEMENT , ULTRATECH CEMENT and others

Thermography can be applied in any situation where a problem or condition can reveal itself by means of a thermal difference. For many situations, this is quite easy to apply; a thermal condition can be seen because the process involves release of thermal energy.

Thermography camera sets from FLIR systems with software. The instrument is capable of scanning surfaces in seconds and can store images. It has supporting latest software which enables customized report preparation indicating temperatures of area, spot, line, delta-T & thermal profile.

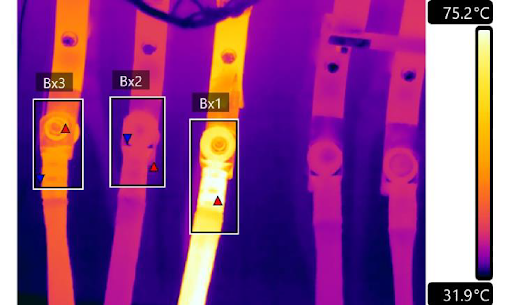

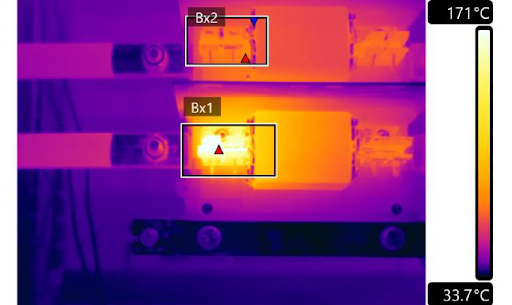

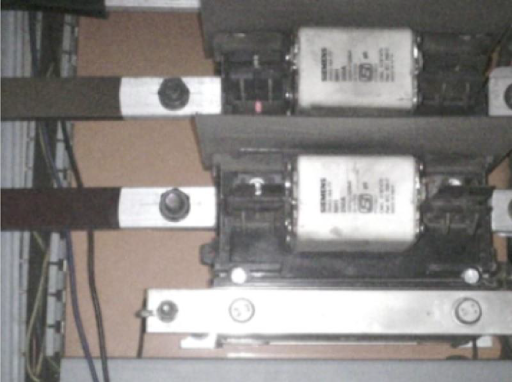

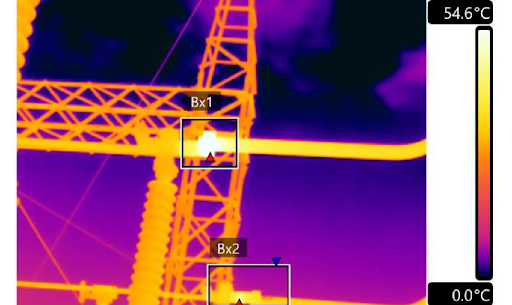

Electrical surveys can identify defects such as poor connections, over loaded cables and faulty electrical equipment.

Thermography is becoming the most reliable diagnostic tool in electrical equipment maintenance. Indoor and outdoor equipment such as panels, switches, relays, transformers, cables, power grids, overhead transmission line etc. can be examined easily. Temperature variations unseen by the human eye can be detected instantly before any major events.

When electrical current passes through a resistive element, heat is generated; we can see that heat with an infrared camera. Sliding and bolted connections can become resistive through loosening, corrosion, etc. This increase in electrical resistance usually results in increase in heat generation and the camera can quickly detect it. A loose connection can dramatically influence neighbor components, raise temperature and reduce the life span of components and insulations, destroy the connector or switch due to arcs, raise power consumption and reduce voltage.

Another issue is the uneven loading of the phase’s resulting malfunctions or interference to the grid. There is no faster and easier way to detect those problems than infrared scanning of the power cables.

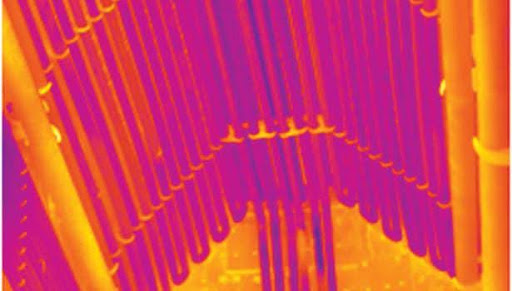

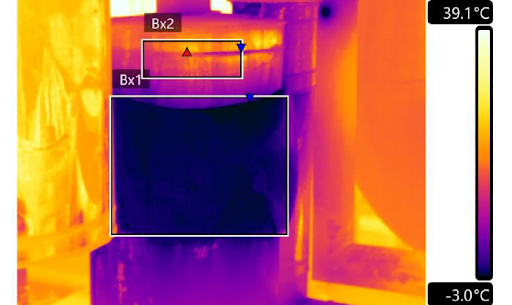

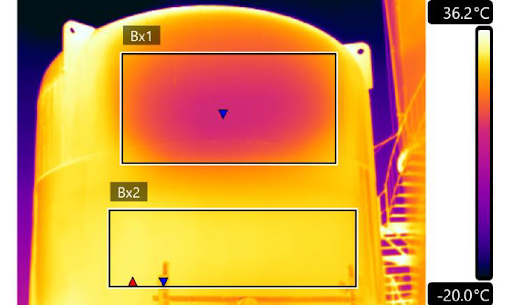

We inspect Furnace, boiler and refractory equipment under normal loads and operating conditions. By performing an infrared scan of your boiler and refractory system in real time. Our inspection can help you understand the practical impacts of emerging or existing Furnace, boiler, process heater, refractory equipment, pipeline, and cold storage problems.

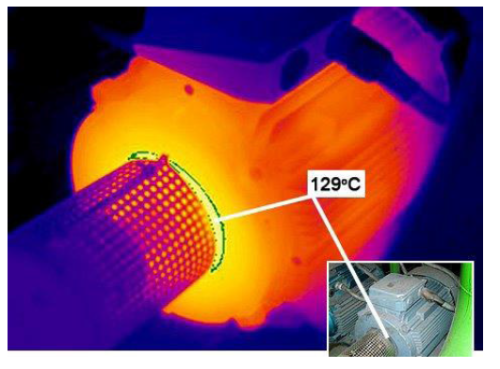

All mechanical systems generate thermal energy during normal operation which allows infrared Thermography to evaluate the operating condition. One of the biggest problems in mechanical systems is excessive temperature. This excessive heat can be generated by friction, cooling degradation, material loss or blockages. An excessive amount of friction can be caused by wear, misalignment, over or under lubrication and misuse. Since most equipment or processes are designed to eliminate thermal energy under normal operation, simply identifying a thermal pattern does not mean a problem has been located. The Thermographer must be familiar with the mechanical components being evaluated. Once a normal thermal pattern is obtained and understood, any deviation from this normal pattern will then provide evidence of a suspect problem developing. Thermography is an excellent tool for locating a problem on mechanical components.

The furnace is inspected with the intention of finding out if the tubes were operating within the design temperature limits or not. The primary aim is to check whether the furnace tubes are coked or not. If it is coked decoking of the tubes during the shutdown is necessary. Flame impingement causes coking to take place.